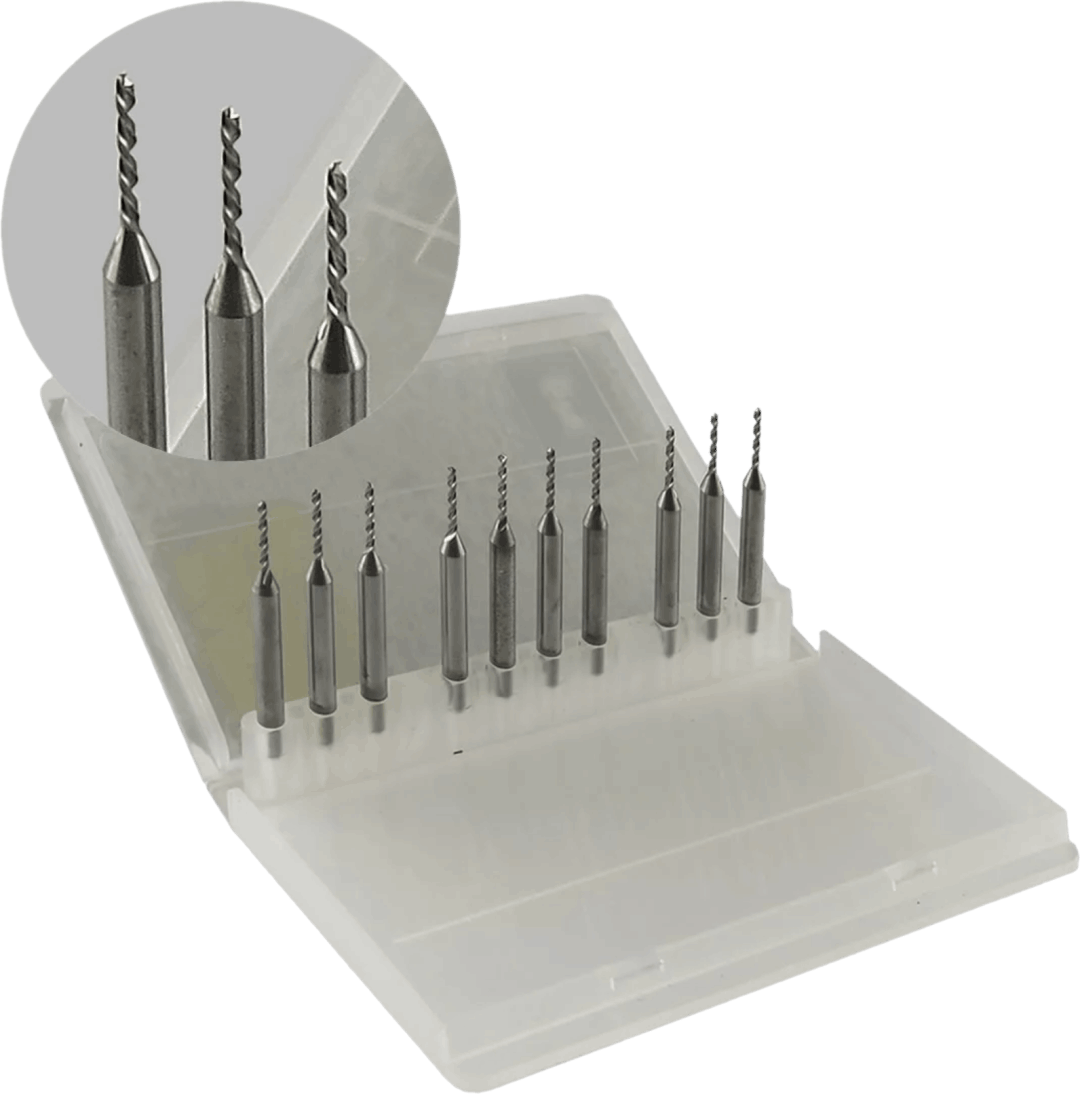

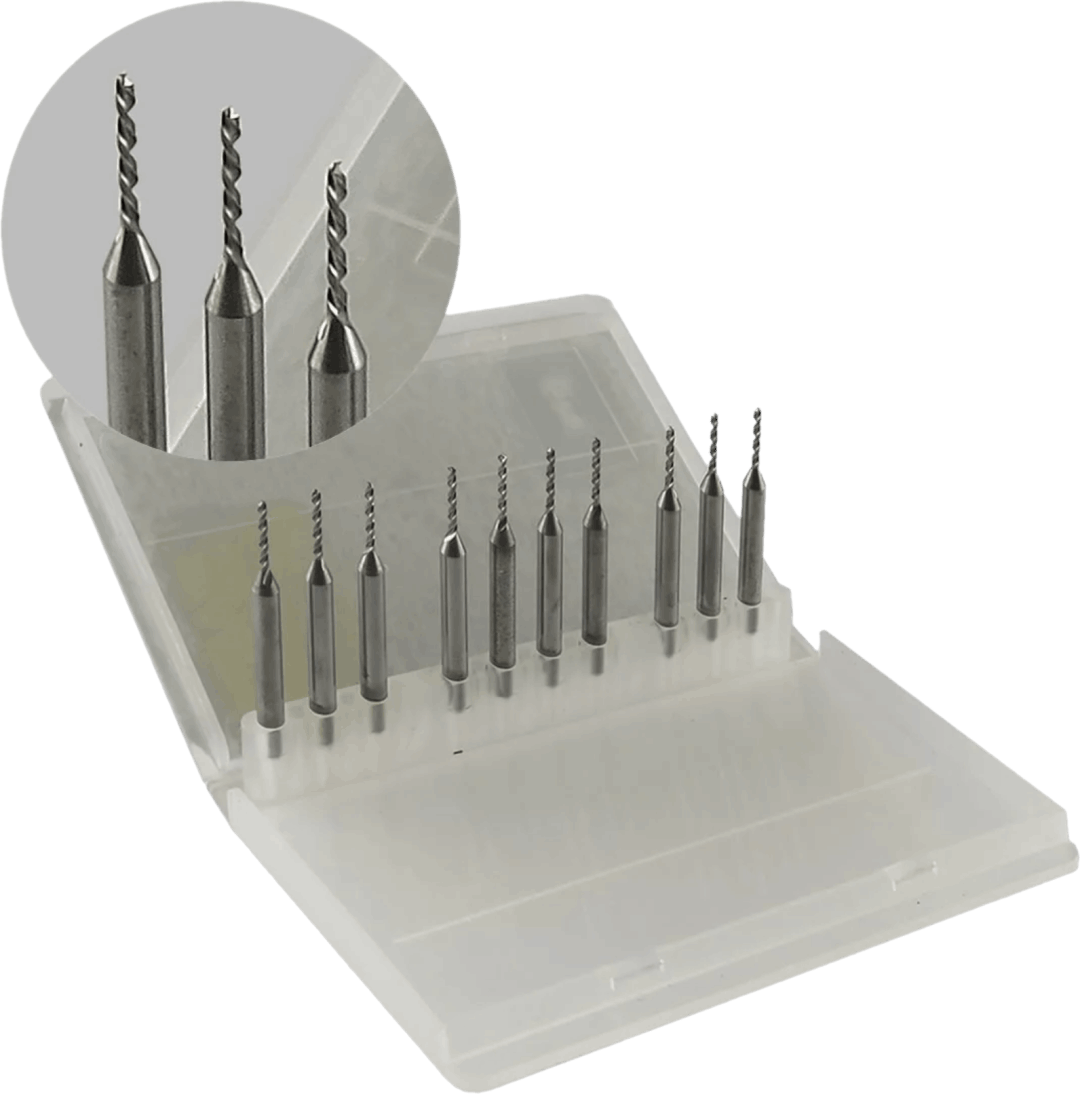

Carbide PCB Drills

3.15mm 1/8" shanks

Solid carbide drill element

Designed for high speed equipment operating up to 80,000 RPM

Can be used at lower speeds by using a slower feed rate

We hold stock of standard drills in the ST and UC Series. The ST Series are a universal drill bit witch can be used for many materials. The UC Series bits are and undercut bit which is used for small through holes or via interconnectors, they allow improved inner hole wall quality, whilst maintaining good registration accuracy. This makes them ideal for high density multilayer boards.

These drill bits are perfect for drilling FR-4 circuit board materials.

The drill element is fabricated of solid carbide since carbide is the preferred material for drilling glass epoxy circuit board laminates due to its exceptional hardness.

We also stock Extended Flute Drills of the STX series which have elongated flutes in comparison to the equivalent standard version in the same diameter.

Finally we stock Micro Drills in the MV and MC Series these are ideal for through holes and blind via hole drilling. These drills are made of hyper fine grade carbide alloy to ensure they are robust.

Due to the brittleness of carbide these drill bits are recommended for use with drill presses or precision equipment.

Care must be taken not to drop or flex them as breakage may occur.

These carbide bits are capable of several hundred or even thousands of hits before significant degradation of sharpness. The number of holes that can be drilled is dependent on a number of factors including feed rate, speed, material characteristics, and what the user considers acceptable hole quality.

We recommend that bits are fitted with depth setting rings This will allow you to set the plunge depth stop on your drill press to a single value that will work for all bit diameters.

All of our bits can be purchased with or without rings. When ordering drills with depth rings, you may specify the depth ring position to suit your requirements.

Review our Depth Ring Setting Page

We offer a wide range of drill sizes from stock, ranging from 0.1mm through to 3.5mm. Running on 3.15mm 1/8" shanks

Our standard drills can operate at upto 80,000 RPM. You should run the drill as fast as possible whilst not exceeding the maximum rated speed. Plunge rate and dwell time should be adjusted to provide best hole quality and minimal burr.

Refer to the Technical Data Sheet for specific recommendations.

PCB drill entry and exit materials prevent burring and keep drills on target to eliminate offsets. We generally recommend aluminium entry sheets and fibreboard or phenolic exit formulas to keep drill bits sharper for longer and avoid burning to preserve PCB integrity.

We do not offer this service.

It is possible, but we do not recommend it. When it comes to drill bits for the PCB industry, the drill point and its sharpness have a dramatic effect on the final Yield of the completed board.

We recommend investing in entry and exit materials to help preserve bit sharpness and ultrasonic cleaning before use.

Resharpening can result in a reduction in flute length.

Yes, we offer a ring setting service. We can fit rings to your drills at the time of purchase. We will keep a record of your drill ring distances, so that upon re-order, we can set the rings to the same position. Review our drill ring setting page.